|

|

|

|

|

|

|

|

|

|

|

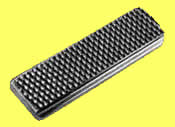

"Precision Ground Carbide Blades"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Our blades are made of a special grade of Tungsten Carbide especially developed to give both the edge wear resistance and the shock resistance necessary for floating horses' teeth. The hard but brittle carbide is supported by a stainless steel backing that is bonded to the carbide to help protect it from cracking. Without the backing, it would be subject to breaking or splintering from simple things. For example, dropping it on a concrete floor or from a horse biting on a blade in use. Stainless steel gives very positive support as compared to aluminum which is weak and flimsy.

Gold series blades are the blades that started a revolution in the floating of horses' teeth. Made of a metal so hard that it will machine the hardest steels, they cut quickly and last a long time. This translates into an easier and shorter task for the equine dentist. We have reports that what used to take 4 hours can be done in 20 minutes. This also means that the practitioners arms and body is saved from an arduous task.

Available in four standard lengths, they fit most handles that are in common use. We, in fact, manufacture handles especially made for these blades. A proper handle is not the light weight stamped steel handles that are sold at cheap prices. A proper handle for these blades has enough weight and strength to it that it glides easily and effortless through the cut without chatter.

A beginner to the use of our Precision Ground Blades™ should start with the "S" blade as it will cut so fast it will surprise you. Only after you have gained experience should you progress to the larger tooth "M" and "L" blades.

Gold Series Blades

These are our top of the line blades, thus the "Gold" designation. The tooth design is similar in shape to a diamond and they cut like many diamonds in a row. Multiple rows of them make a very sharp blade that trims or "floats" horses' teeth very fast. These blades last longer as the diamond shaped teeth, if they chip, get smaller chips. This means that less material has to be removed in re sharpening, prolonging the life of the blade.

|

|

|

|

|

|

|

|

|

|

"S"

|

"M"

|

"L"

|

Smooth

|

Best Seller

|

Aggressive

|

|

|

Blade tooth sizes shown above are enlarged so you can easily see the tooth design. Note that only the size of the teeth change, the design is the same on all three blades.

"S" Blade: This is the original tooth size and design that started a revolution in the state of the art of floating horses teeth. The cut is smooth and sharp. There are more points to do the cutting, therefore, the life of the blade is extended. Also, on regrinding, less material is removed from the blade thickness and this increases blade life. If you have been using carbide chip blades, you will be delighted to "discover" these blades.

"M" Blade: Practitioners that became accustomed to the "S" blades thought they could handle a larger tooth blade that would cut faster. Therefore the "M" blade was born. To their surprise, this proved to be their choice of a blade that was very fast cutting, yet did most jobs well.

"L" Blade: A lot of material has to be removed from some horses teeth. The "L" blade was born from this need to get at the work and get it done. Most practitioners have some "L" blades in their blade box, and some have become so used to them that its all they use.

Blades will fit most handles but they work best in our handles which are especially made for our carbide Precision Ground Blades™. See the handle section of this web site for the handles that are rugged enough to do the work that these blades will do.

|

|

|

|

|

|

|

Blades are 3-1/4" long (82.6 MM.), 1" wide.

#S-314 - Smooth cutting, long life.

#M-314 - Fast, gets the job done.

#L-314 - Aggressive

|

|

Blades are 3" long (76.2 MM.), 1" wide.

#S-3 - Smooth cutting, long life.

#M-3 - Fast, gets the job done.

#L-3 - Aggressive

|

|

Blades are 2-1/4" long (57.2 MM.), 1" wide.

#S-214 - Smooth cutting, long life.

#M-214 - Fast. Gets the job done.

#L-214 - Aggressive

|

|

Blades are 1-1/2 " long (38.1 MM.), 1" wide.

#S-112 - Smooth cutting, long life.

#M-112 - Fast, gets the job done.

#L-112 - Aggressive

|

|

|

|

|

|

|

|

|

|

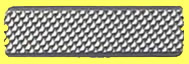

Silver Series Blades™

The desire to make a somewhat lower cost blade led us to developing the "Silver" series of blades. If a blade stays on the grinding machine a shorter period of time, it obviously can cost less money to make. The "Gold" series of blades require a longer time to grind because each tooth comes to an almost sharp point. This means the second cut in the cross cut pattern takes about as much time as the first cut as it has an almost equal number of cuts. By extending the spacing on the second cut to reduce the number of cuts made, two things happen. First, the tooth takes a wide or broad tooth appearance because it is broad. Second the number of cuts is reduced, therefore it can be ground cheaper. We introduced the broad faced "Silver" series to the market and they have been well received by many practitioners.

|

|

|

|

|

|

|

|

"E"

|

"N"

|

"Z"

|

"R"

|

Smooth Cut

|

Medium Cut

|

Aggressive

|

Very Aggressive

|

|

|

|

Blade tooth sizes as shown above are enlarged so you can see the tooth design. Note that the design changes somewhat depending upon what the blade was designed to do.

"E" Blade: This blade is designed to cut silky smooth in areas that you want to just shave off the surface to make it smooth or to remove minor blemishes.

"N" Blade: This is a general purpose blade that will get the job done with the least chipping and maintain it's sharpness the longest.

"Z" Blade: When you have a lot of work to be done on an old horse with very hard teeth you need something that will cut fast without a lot of effort or chipping. This blade does this job superbly.

"R" Blade: There are times when the amount of work to be done leaves you a little tired before you start. You want something that will do the cutting and save your arms. At those times, this is the blade for you.

These blades will fit most handles but they work best in our handles which are especially made for our carbide "Precision Ground Blades™. See the handle section of this web site for the handles that are rugged enough to do the work that these blades will do.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

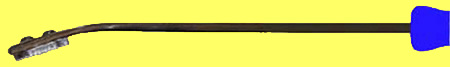

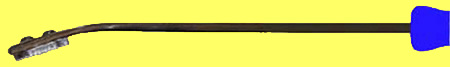

Pocket Blades™

Designed for our Ultra Slim™ pocket handles. These blades are used for miniature horse handles as well as the #6LP flat shaft handles for the last molars. In addition, any of our standard handles can be had in a pocket handle version. Also, they are used in the pocket handles for the MAKITA® reciprocating units. These blades take up a minimum of space and can be easily removed by taking out 2 screws that secure the blades from the rear of the handles. It is therefore easy to either change blades or return them to us for re sharpening.

|

|

|

|

|

|

|

|

#PBN114 shown above

|

# PBN214 shown above

|

|

|

|

|

|

|

|

These are the thinnest replaceable blades on the market that can easily be taken out of a handle and sent for re sharpening.

|

|

|

Blade is 2-1/4" long (57.2 MM) and 3/4" (19.2 MM) wide.

Gold Series "S" & "M" and Silver Series "N" & "Z blades are carried in stock.

|

|

Blade is 1-1/4" long (31.8 MM.) and 3/4" (19.2 MM) wide.

Gold Series "S" & "M" and Silver Series "N" & "Z blades are carried in stock.

|

|

|

|

Pocket Blades™ are primarily used in power equipment such as the MAKITA® Reciprocating Unit. The "N" and "Z" cuts are usually used as the diamond shaped teeth of the "Gold" series cut very aggressive under power. The "Silver" series blades slow this aggressiveness down to manageable proportions.

Pocket Blades™ are also used in certain handles that require thinness to accomplish the work. One such handle is the #6LP shown below which is designed to reach back to the last molar and accomplish the work required on the back-side of the tooth. This handle is shown below.

|

|

|

#6LP Ultra Slim™ Pocket Handle™ shown above is in the handle section of this web site.

|

|

|

|

|

|

|

|

|

About our new blades and re sharpening service.

The same CNC machines that grind new blades are used to re sharpen worn and chipped blades to "as new" condition. The blade rails are also thinned as needed to allow the blade teeth to extend above a handle head. Also, we dull the leading blade edge to prevent it's sharpness from easily cutting a horse. Construction consists of solid carbide securely bonded into a supporting stainless backing. We stock new blades. For re sharpening, please allow 1 to 2 weeks for turn around time. We do not re sharpen blades using the "off hand" method which ruins tooth shape and spacing.

Please Note: There are no industry manufacturing tolerances or carbide grade standards for the manufacture of either blades or carbide burrs. Therefore, what you buy on the market from other sources may or may not do your job to your satisfaction. For burrs, they may even ruin your guards. To be sure of what you are buying, please use our close tolerance burrs. This is the only way you can be sure that the burrs will cut properly and not chew up your guards.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|